Mobile: +86 176 2011 9866

Mobile: +86 176 2011 9866

Mobile: +86 176 2011 9866

Mobile: +86 176 2011 9866

Achieve perfect case packing for pouches without affecting production efficiency.

Austrian KEBA Control System is used in 3-in-1 packaging system , stressing on USABILITY and visualization. Packing plan can be setup by operator in a matter of minutes.

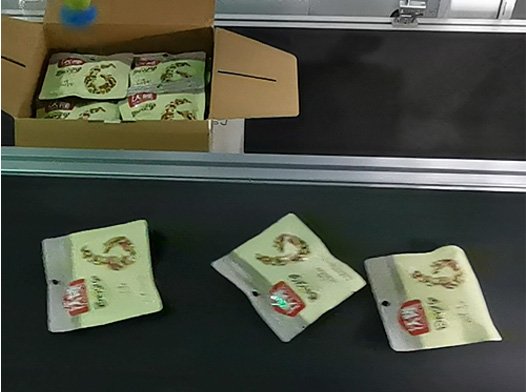

Pouches coming from conveyor in random placement can be quickly recognized , picked accurately, and placed orderly.

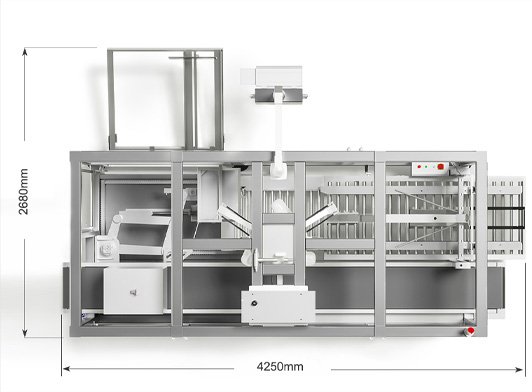

The machine expanded volume is only L4250 x L2680 x H2617mm.

Our machine is stable and reliable with few vulnerable parts. We also provide certain spare parts freely enough for you to use 2+ years, super cost-effective price to you if want more spare parts.

Almost applicable for any common types of plastic pouches.

Welcome for trial testing if your pouch is not included in table below.

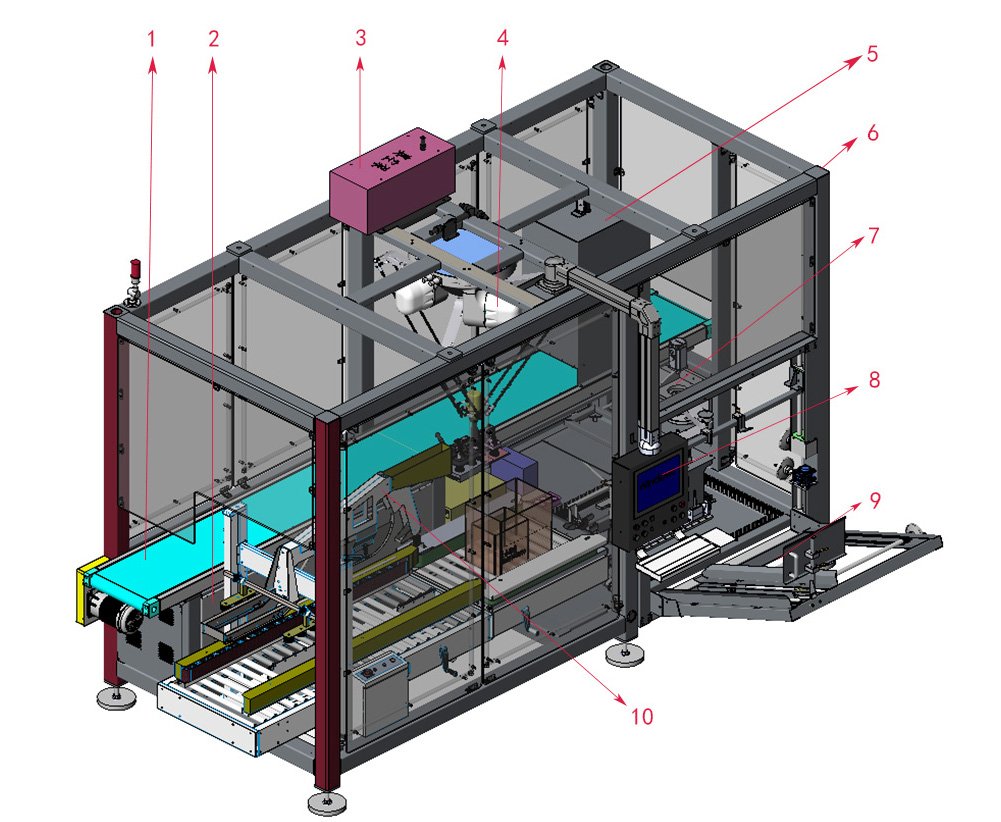

1. Infeed conveyor 2. Electric box

3. Vacuum pump 4. Delta robot

5. Vision system

6. Frame 7. Case erector 8. HMI

9. Case storage area 10. Case sealer

| Technical introduction | |

| Allowable Bags Size | L50-500*W50-450*H5-100(mm) |

| Allowable Cases Size | L260-500*W200-450*H150-400(mm) |

| Case Material Requirements | ≥ 3-layer corrugated paper |

| Robot Speed | 40-120PPM,different products,the speed may vary. |

| Case Erector Speed | 6 per min |

| Conveyor Belt Height | Infeed:H950mm; Outfeed:H540mm |

| Robot Payload | 5kg ,include EOAT |

| Controller | KEBA |

| Instruction Types | PTP、LINE、PLACE |

| Pressure | 0.6-0.8Mpa |

| Protocol | EtherCAT,Modbus TCP/IP,CAN,RS485 |

| Frame Material | Carbon Steel / SUS304#Stainless Steel |

| IP Level | IP54 |

| OAT | -5-45℃ |

| Ambient Humidity | ≤75%(No condensation) |

| Voltage | 3 phase,380V/Customization |

| Power | 8KW |

| Noise Level | ≤85 dB |

| Size | L4227xW2678xH2617mm |

| Height | 2000kg |